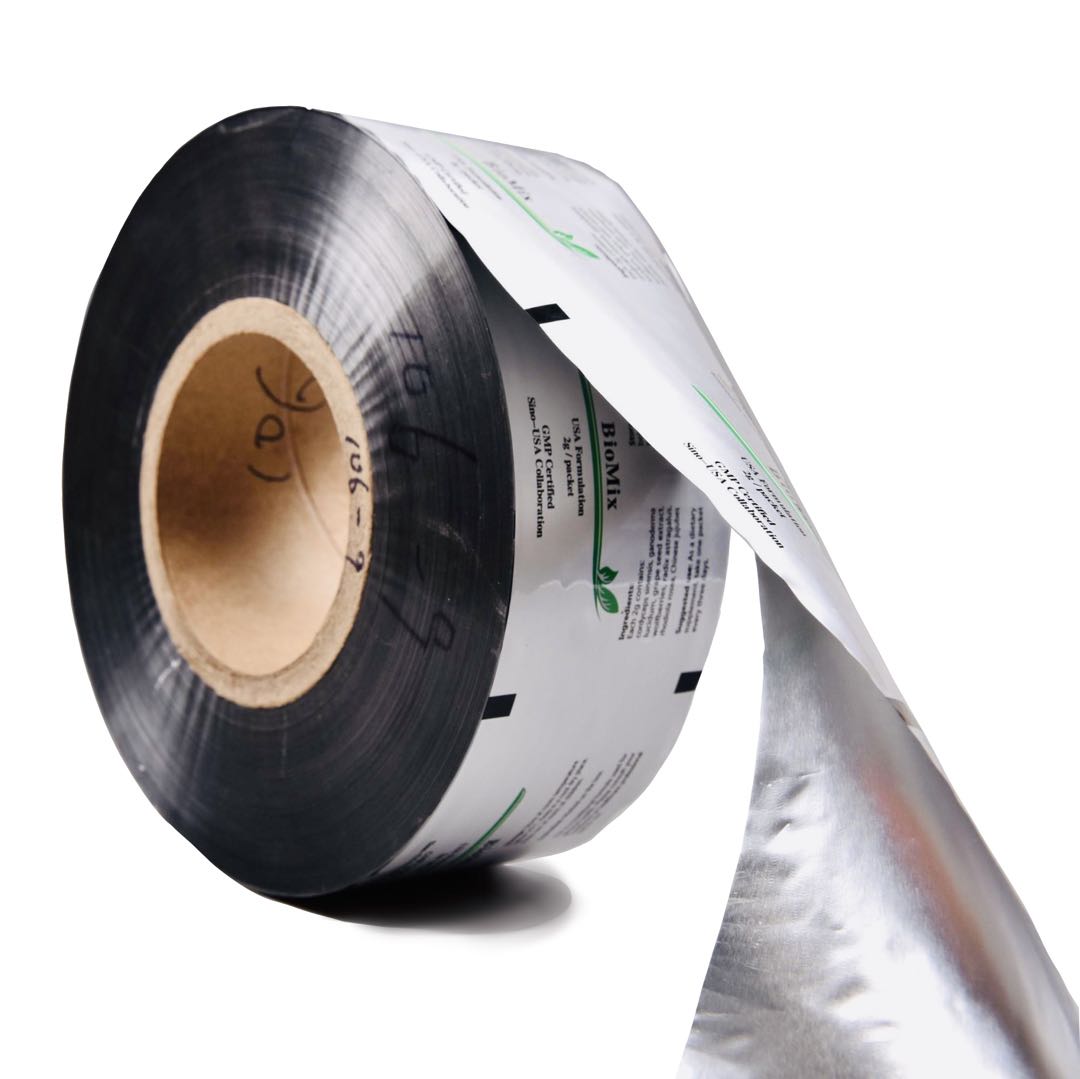

Pet Snack Goat Milk Stick Packaging Roll Film

Pet Snack Goat Milk Sticks Packaging - Product Challenges

Goat milk sticks are high-protein, high-fat pet snacks popular in the market for their nutrition and palatability. However, their sensitive properties create significant packaging challenges:

* Oxidation risk: Fats are highly prone to oxidation upon exposure to air, causing color changes and flavor degradation.

* Volatile flavor loss: Insufficient barrier packaging can result in aroma loss or cross-contamination of external odors.

* Batch inconsistency: Variations in packaging barrier performance can lead to inconsistent product quality, affecting brand reputation and increasing returns.

These challenges directly impact consumer experience, product return rates, and brand trust, making packaging a critical control point in the supply chain.

Roll Film - High-Barrier Packaging Value

To address these challenges, we provide high-barrier film packaging solutions designed for pet snacks like goat milk sticks. The core benefits include:

1. Oxygen Transmission Control

* Significantly reduces oxygen penetration, slowing fat oxidation and maintaining original color and visual appeal.

2. Moisture Migration Control

* Minimizes water vapor transfer, preventing softening or texture change, and maintaining flavor stability.

3. Light Protection

* High opacity or light-blocking properties protect products from light-induced chemical reactions, preserving both color and aroma.

4. Flavor and Aroma Retention

* Stable barrier structure reduces aroma loss and prevents contamination from external odors, supporting long-distance shipping and prolonged shelf life.

The following are real-life photos, all showing the actual products.

Roll Film - Technical Validation and Data

| Test Item | Unit | Technical Requirement | Test Result | Judgment | |||||

| Oxygen Transmission Rate (OTR) | cm³ / (m²·24h·0.1MPa) | ≤ 1800 | 0.345 | Pass | |||||

| Water Vapor Transmission Rate (WVTR) | g / (m²·24h) | ≤ 5.8 | 0.663 | Pass | |||||

| Total Residual Solvents | mg/m² | ≤ 5.0 | Not Detected (<0.01) | Pass | |||||

| Benzene-based Solvent Residue | mg/m² | Not Detected | Not Detected (<0.01) | Pass | |||||

| Heavy Metals (as Pb) (4% Acetic Acid, 60°C, 2h) | mg/kg | ≤ 1 | < 1 | Pass | |||||

| Test Conditions | |||||||||

| The Water Vapor Transmission Rate (WVTR) test was conducted under the conditions of 38°C and 90% relative humidity (RH). | |||||||||

| All other test items were carried out under the environmental conditions of 23°C and 50% relative humidity (RH). | |||||||||

Quality Risk Control and Process Recommendations

For B2B procurement and production teams, high-barrier packaging should be assessed and implemented with clear control measures:

1. Define material performance criteria

Establish acceptable OTR/WVTR and sensory retention standards.

2. Third-party verification or lab testing

Engage qualified labs to validate barrier performance and generate formal reports.

3. Small-batch pilot testing

Conduct trial runs on production lines to confirm seal integrity, machine compatibility, and finished product consistency.

4. Collaboration with product formulation and process

Coordinate with formulation, fill, and sealing conditions to optimize overall performance.

Summary and Procurement Considerations

For pet snack brands and OEM/ODM factories, high-barrier packaging is not just a material choice but a strategic control point ensuring:

* Consistent product quality across batches

* Reduced complaints and returns

* Controlled risk in storage and logistics

* Protection of brand reputation

Key evaluation factors for procurement:

* Clearly defined barrier performance (OTR / WVTR)

* Verified lab data supporting performance claims

* Compatibility with production lines and sealing processes

* Sensory and flavor stability evaluation protocols

* Measurable quality control processes

High-barrier packaging ensures long-term product stability and consumer trust, forming a critical foundation for brand success in the pet snack market.