Quality Assurance

Over the past 30 years, Meifeng has earned a good reputation for producing high-quality packaging and films. By invested top class equipment, using first class supplier of materials, ink, glue, and our highly skilled machine operators, we award good feedbacks from our customers. And our products adhere to stringent quality standards to meet the needs of FDA.

Meifeng has approved by BRCGS (Brand Reputation through Compliance Global Standards) Certification for Packaging and Packaging Materials to ensure product safety, integrity, legality and quality, and the operational controls in the food and pet food packaging industry.

The BRCGS Certification is recognized by the GFSI (Global Food Safety Initiative) and provides a robust framework to follow during the production of safe, authentic packaging materials and to better manage product quality to meet customers’ requirements, while maintaining legal compliance for food packaging.

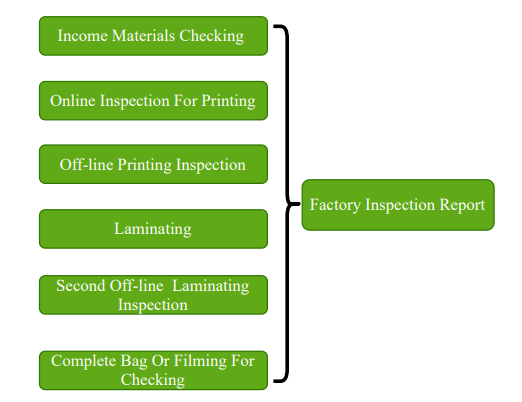

Factory testing report include:

● Friction testing for auto packing films

● Vacuum testing

● Tensile testing

● Interlayer adhesion testing

● Seal strength testing

● Drop testing

● Burst testing

● Puncture resistance testing

Our factory testing report filed last for 1 years, any feedback on after sales, we offer the trace of testing report for you.

We also provide third party report if the clients needed. We have a long-term cooperation with SGS Lab centers, and if there is any other lab you appointed, we can also cooperate in need.

Custom services are our biggest advantage, and a high-quality standard requested is welcomed to challenge in Meifeng. Send us your product requirement and standard level, and then you will have a fast reply from one of our sales reps.

We also help our clients to make prototype testing until they find a 100% suitable package including the size, materials and thickness.