Structures (Materials)

Flexible Pouches, Bags & Rollstock Films

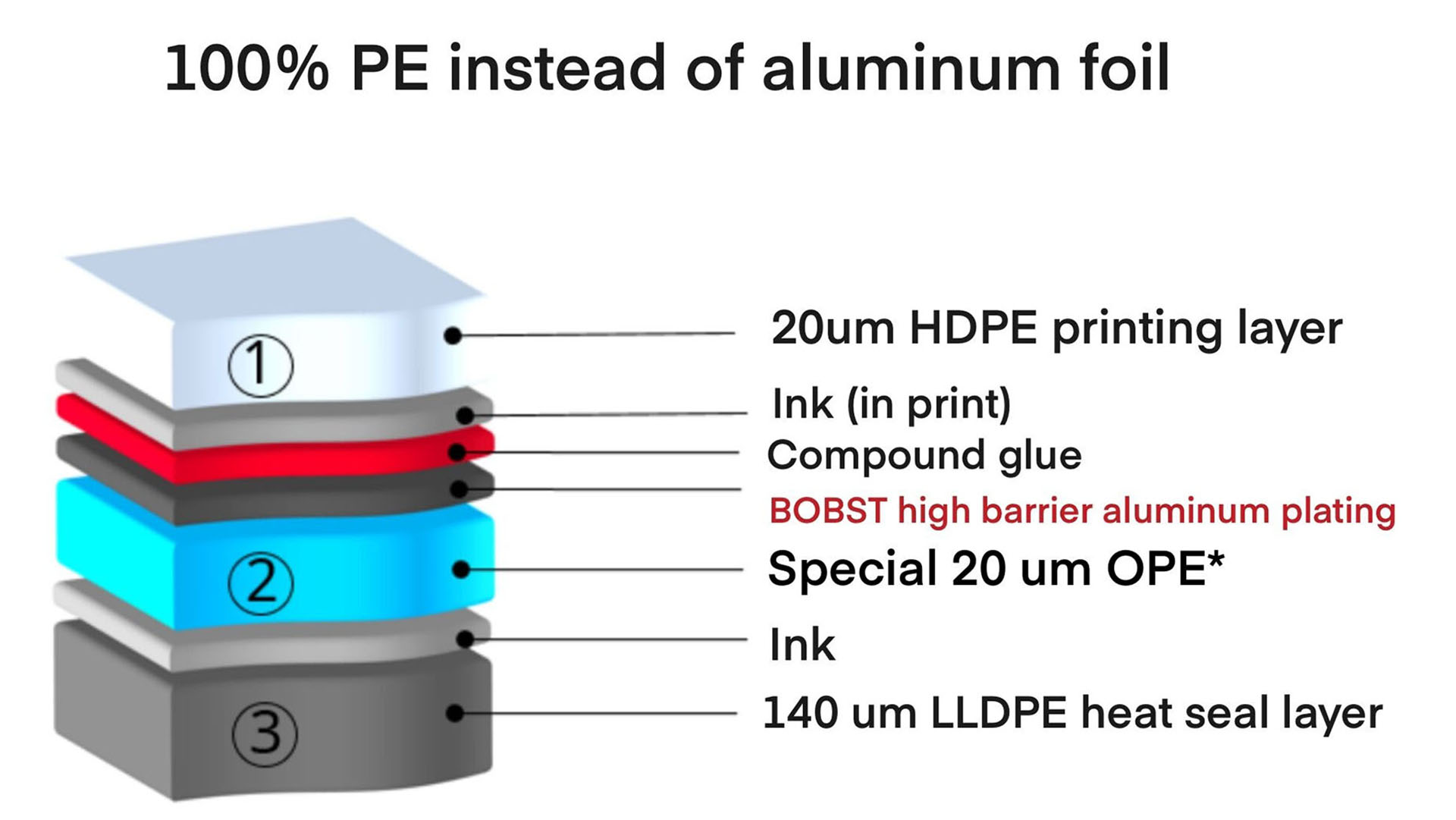

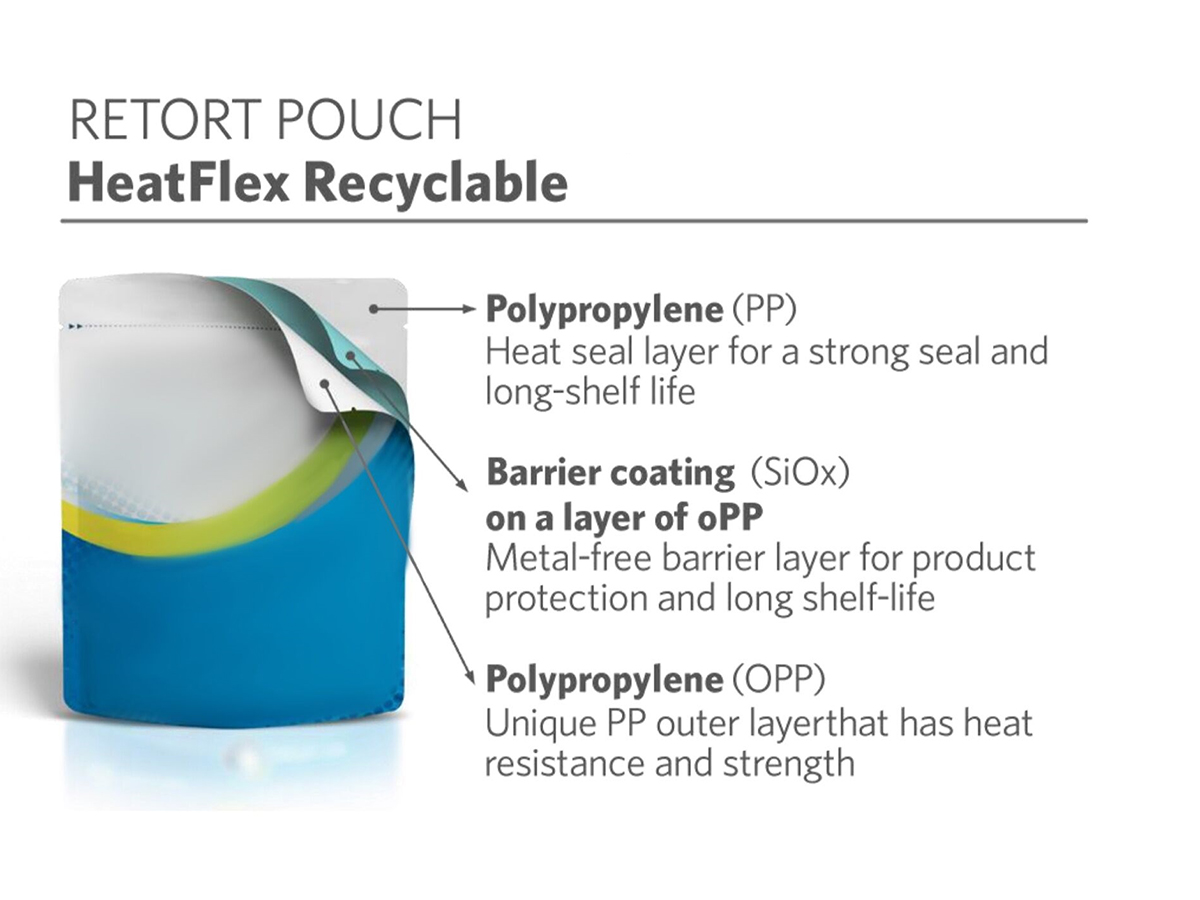

Flexible packaging is laminated by different films, the purpose is to offer a good protection of the inner contents from the effects of oxidation, moisture, light, odour or combinations of these. For commonly used materials structure are distinct by outside layer, middle layer, and inner layer, inks and adhesives.

1. Outside layer:

The outer printing layer is usually made with good mechanical strength, good thermal resistance, good printing suitability and good optical performance. The most commonly used for printable layer are BOPET, BOPA, BOPP and some kraft paper materials.

The requirement of outside layer is like following:

| Factors for checking | Performance |

| Mechanical strength | Pull resistance, tear resistance, impact resistance and friction resistance |

| Barrier | Barrier on oxygen and moisture, aroma, and UV protection. |

| Stableness | Light resistance, oil resistance, organic matter resistance, heat resistance, cold resistance |

| Workability | Friction coefficient, thermal contraction curl |

| Health safety | Nontoxic, light or odor lessness |

| Others | Lightness, transparency, light barrier, whiteness, and printable |

2. Middle Layer

The most commonly used in middle layer is Al (aluminum film), VMCPP, VMPET, KBOPP, KPET, KOPA and EVOH and etc. Middle layer is for barrier of CO2, Oxygen, and Nitrogen to go through the inner packages.

| Factors for checking | Performance |

| Mechanical strength | Pull, tension, tear, impact resistance |

| Barrier | Barrier of water, gas and fragrance |

| Workability | It can be laminated in both surfaces for middle layers |

| Others | Avoid of light go through. |

3. Inner layer

The most important for inner layer is with a good sealing strength. CPP and PE are most popular to use by inner layer.

| Factors for checking | Performance |

| Mechanical strength | Pull resistance, tear resistance, impact resistance and friction resistance |

| Barrier | Keep a good aroma and with a ow adsorption |

| Stableness | Light resistance, oil resistance, organic matter resistance, heat resistance, cold resistance |

| Workability | Friction coefficient, thermal contraction curl |

| Health safety | Nontoxic, odor lessness |

| Others |

Transparency, inpermeable. |