As a leading provider of plastic flexible packaging solutions, we understand the importance of selecting the most suitable printing method for your packaging requirements. Today, we aim to provide insight into two prevalent printing techniques: gravure printing and digital printing.

Gravure Printing:

Gravure printing, also referred to as rotogravure printing, boasts several notable advantages. One significant benefit is its ability to produce high-quality, consistent results, making it the preferred choice for large-scale printing projects.

(Our state-of-the-art Italian BOBST printing machine (up to 9 colors)

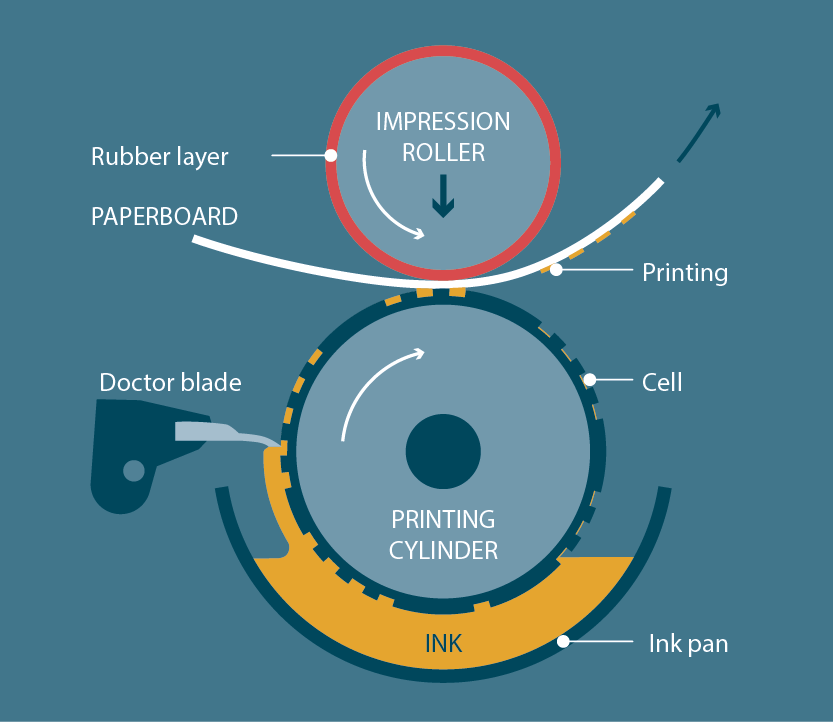

The gravure printing process involves etching images onto cylindrical printing plates, resulting in precise and detailed prints. Moreover, one of the key advantages of gravure printing is that the printing cylinders can be reused, offering cost savings and environmental benefits over time.

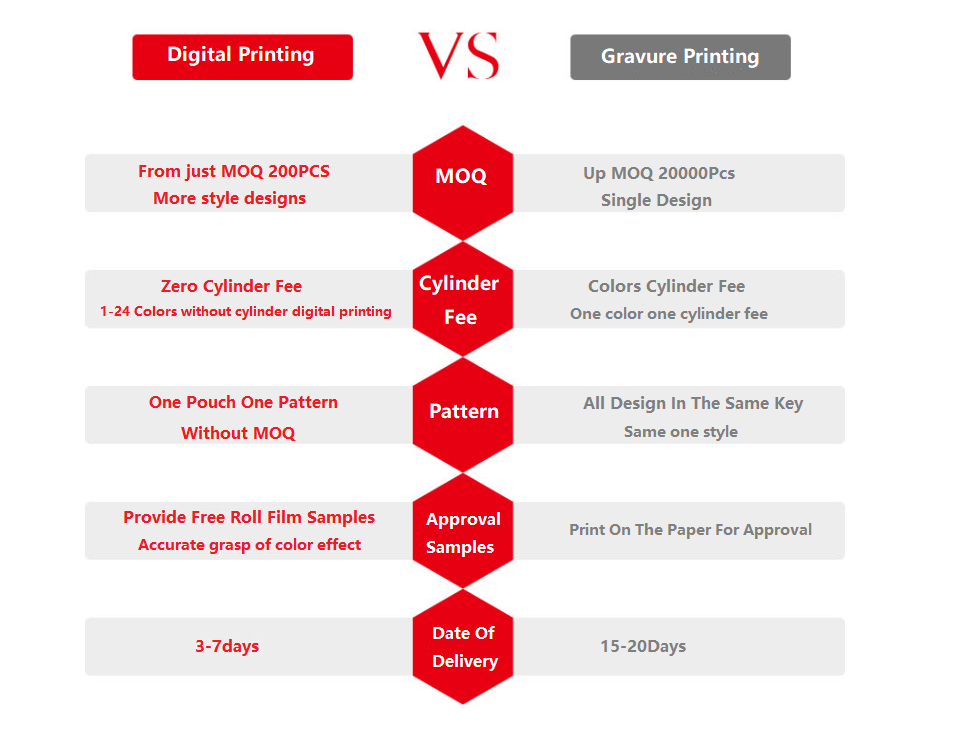

However, it’s important to consider certain drawbacks associated with gravure printing. Firstly, the setup costs can be relatively high due to the need for creating printing cylinders, making it less cost-effective for smaller print runs. Furthermore, gravure printing requires longer setup times and may not be conducive to rapid changes in design or content.

(A sample of gravure printing plates. One plate is required for each color.)

As a result, gravure printing is best suited for long print runs with consistent artwork and higher budget allocations.

Digital Printing:

Digital printing offers unparalleled flexibility and customization, making it an attractive option for businesses requiring shorter print runs and rapid turnaround times. Unlike gravure printing, digital printing does not require the creation of printing plates. Instead, digital files are directly transferred to the printing press, allowing for on-demand printing and quicker setup times. This feature makes digital printing ideal for personalized or variable data printing, where each package can feature unique graphics or content.

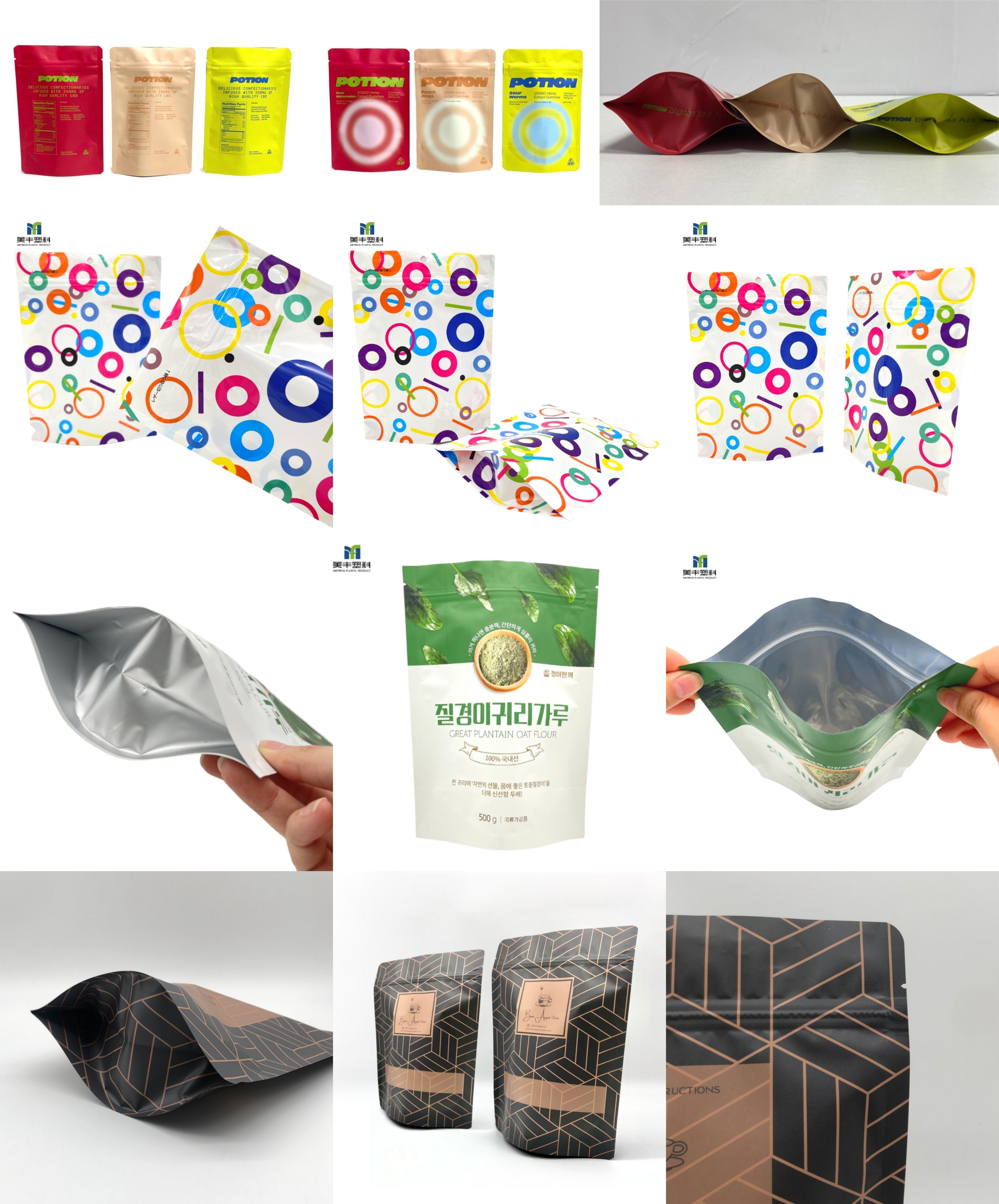

Moreover, digital printing excels in producing vibrant colors and intricate designs, thanks to its high-resolution capabilities. This makes it a preferred choice for brands looking to create eye-catching packaging or seasonal promotions. Additionally, digital printing eliminates the need for minimum order quantities (MOQs), enabling cost-effective solutions for small to medium-sized print runs.

(Some of our samples of digitally printed bags)

However, it’s essential to acknowledge that digital printing may have limitations in achieving the same level of consistency as gravure printing, particularly on specific substrates. Additionally, digital printing cannot be applied to retort pouches due to limitations in ink resistance to retort conditions, making gravure printing the preferred choice for such applications.

Choosing the Right Printing Method:

When selecting between gravure printing and digital printing for your plastic packaging needs, it’s crucial to consider factors such as order volume, budget constraints, design complexity, and lead times. For large-scale productions with consistent artwork and longer print runs, gravure printing may offer the best value proposition. Conversely, digital printing is an excellent choice for businesses seeking flexibility, customization, and cost-effective solutions for smaller print runs or variable data printing projects.

At MEIFENG, we are committed to providing innovative packaging solutions tailored to your unique requirements. Our expert team is here to assist you in choosing the optimal printing method to enhance your brand presence and meet your packaging objectives.

For further inquiries or to discuss your project in detail, please feel free to contact us. Thank you for considering MEIFENG as your trusted packaging partner.

Post time: Feb-26-2024