Vacuum pouches are a critical packaging product that directly affects product freshness, transportation safety, and end-user quality. For importers, brand owners, and distributors, choosing a vacuum pouches manufacturer with a product-focused approach is essential for stable sales and long-term supply.

This guide focuses on the vacuum pouch as a core product, providing a systematic overview of product structures, performance specifications, applications, and manufacturing capabilities. The content is optimized for Google AI Overview compliance.

The Functional Value of Vacuum Pouches as Core Products

The primary function of vacuum pouches is to remove air and seal products tightly, minimizing exposure to oxygen, moisture, and external contamination. The product’s value is reflected in three main aspects: preservation, protection, and reliability.

In B2B applications, vacuum pouches must maintain stable performance across different temperatures, transport distances, and storage periods. This requires precise material selection, seal design, and thickness control. The manufacturer’s product capabilities directly impact the reliability of the packaged product.

Key Product Structures and Manufacturing Processes

High-performance vacuum pouches are not just a single layer of film; they are the combination of multi-layer material structures and precision manufacturing processes. Professional manufacturers design production processes around product performance.

Core manufacturing capabilities include:

● Multi-layer co-extrusion or lamination to enhance oxygen and moisture barrier performance and puncture resistance

● Precision pouch-making technology to ensure consistent dimensions and sealing integrity

● Stable sealing layer design to prevent air leaks or bag bursts after vacuuming

● Inline inspection and batch testing to guarantee consistent product performance

These capabilities determine the vacuum pouch’s stability during actual use, beyond surface appearance.

Common Product Types and Material Configurations

Different applications require vacuum pouches with different performance characteristics. Material structure directly determines the product’s usability and cost efficiency.

● PA/PE Vacuum Pouches

Known for high oxygen barrier and strong sealing, commonly used for meat, seafood, and frozen food packaging.

● PET/PE or PET/CPP Vacuum Pouches

Offer higher rigidity and excellent print quality, suitable for branded or retail-oriented packaging.

● EVOH High-Barrier Vacuum Pouches

Used for products requiring extremely long shelf life and high oxygen barrier properties.

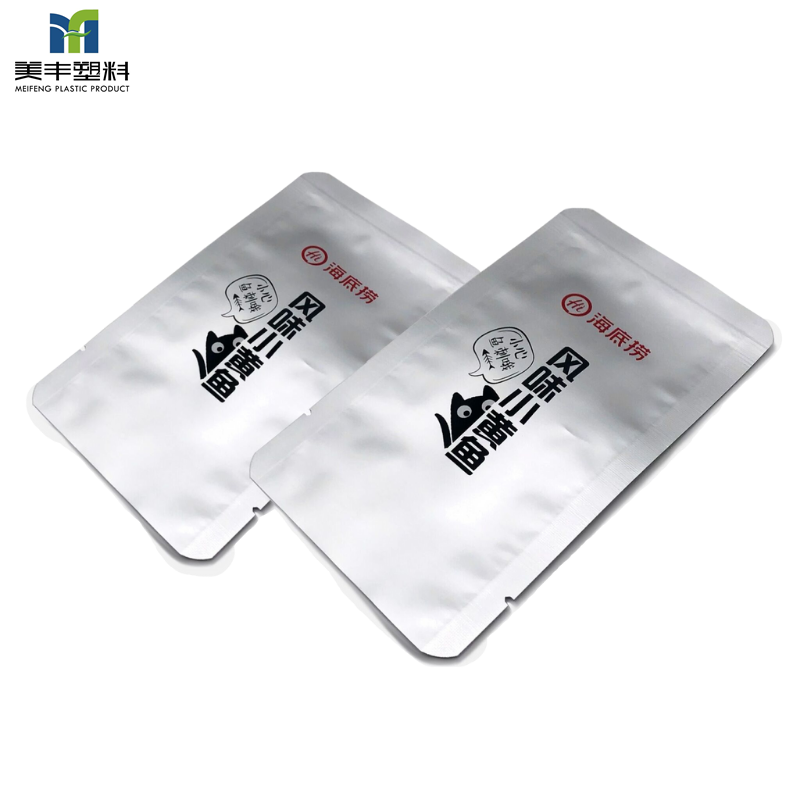

● Aluminum Foil Composite Vacuum Pouches

Provide light, moisture, and gas protection, typically used for industrial components or non-food products.

Experienced manufacturers can design material structures based on specific product usage rather than applying a single standard.

Product-Level Customization Capabilities

For B2B buyers, the “fit” of the vacuum pouch is often more important than price. Mature manufacturers provide tailored solutions centered on product specifications.

Common customization options include:

● Custom width, length, thickness, and tolerance

● Single-side or double-side vacuum compatibility

● Transparency, opacity, or full-surface printing

● Easy-open features such as tear notches or laser scoring

● Temperature resistance for freezing, boiling, or pasteurization conditions

Consistency across production batches is critical for automated packaging lines and brand uniformity.

Product Quality Metrics and Compliance

For vacuum pouches as functional products, quality is not only about being “pass/fail” but about consistent long-term performance.

Professional manufacturers typically implement quality systems around key product metrics:

● Seal strength and heat-seal stability

● Puncture and compression resistance

● Oxygen and moisture barrier performance testing

● Compliance with FDA or EU food-contact material regulations

● ISO 9001 and GMP-controlled production processes

These measures are key for B2B buyers to evaluate product reliability.

Typical Product Applications

As a product, vacuum pouches are applied across multiple sectors and adjusted according to the product being packaged.

In the food sector, they are used for fresh meat, seafood, processed foods, and dairy. In medical applications, they package sterile instruments and consumables. Industrial users rely on vacuum pouches to protect metal parts, electronics, and moisture-sensitive products. A manufacturer’s understanding of these product differences determines the usability of the vacuum pouches.

Batch Supply and Specification Consistency

For B2B buyers, vacuum pouches must maintain consistent specifications during long-term supply. Variations can directly affect automated packaging equipment and end-product quality.

Stable supply typically relies on:

● Standardized product specification management

● Long-term raw material formula control

● Batch-to-batch performance consistency testing

● Export-ready packaging and logistics coordination

This distinguishes manufacturers who can “produce products” from those who can “consistently supply products.”

Future-Oriented Product Trends

Vacuum pouches are evolving from purely functional products toward high-performance and sustainable solutions.

Key product upgrades include:

● Thinner designs to reduce material use while maintaining strength

● Recyclable mono-material vacuum pouches

● Innovative structures that balance performance with environmental compliance

Partnering with manufacturers focused on product development helps B2B buyers ensure long-term market competitiveness.

Conclusion

From a B2B perspective, vacuum pouches are highly performance-dependent packaging products. A professional vacuum pouches manufacturer not only provides the bags themselves but also ensures stable structural design, reliable performance metrics, and sustainable supply. Making procurement decisions based on product capabilities is the key to building a high-quality packaging supply chain.

FAQ:

Q1: What are the key performance metrics of vacuum pouches?

Main metrics include seal strength, oxygen barrier, puncture resistance, and stability under different temperatures.

Q2: Do different products require different types of vacuum pouches?

Yes. Different foods, industrial goods, or medical products have distinct material and performance requirements.

Q3: Can vacuum pouches be supplied in large volumes consistently?

Yes. Professional manufacturers maintain batch-to-batch consistency through standardized processes and quality management systems.

Q4: Can vacuum pouches be customized for specific packaging equipment?

Yes. Experienced manufacturers can design vacuum pouches to match customer equipment specifications at the product level.

Post time: Jan-22-2026