The food industry is constantly innovating to meet the evolving demands of consumers and businesses alike. In a world where efficiency, food safety, and extended shelf life are paramount, a revolutionary technology has emerged as a game-changer: retort food. More than just a packaging method, it is a sophisticated process that allows food to be shelf-stable for months or even years without the need for refrigeration or preservatives.

For B2B buyers in sectors like food service, retail, and emergency preparedness, understanding retort technology is crucial. It offers a unique combination of culinary quality, logistical efficiency, and unparalleled safety, making it a powerful solution for streamlining operations and expanding product lines.

What Exactly is Retort Food?

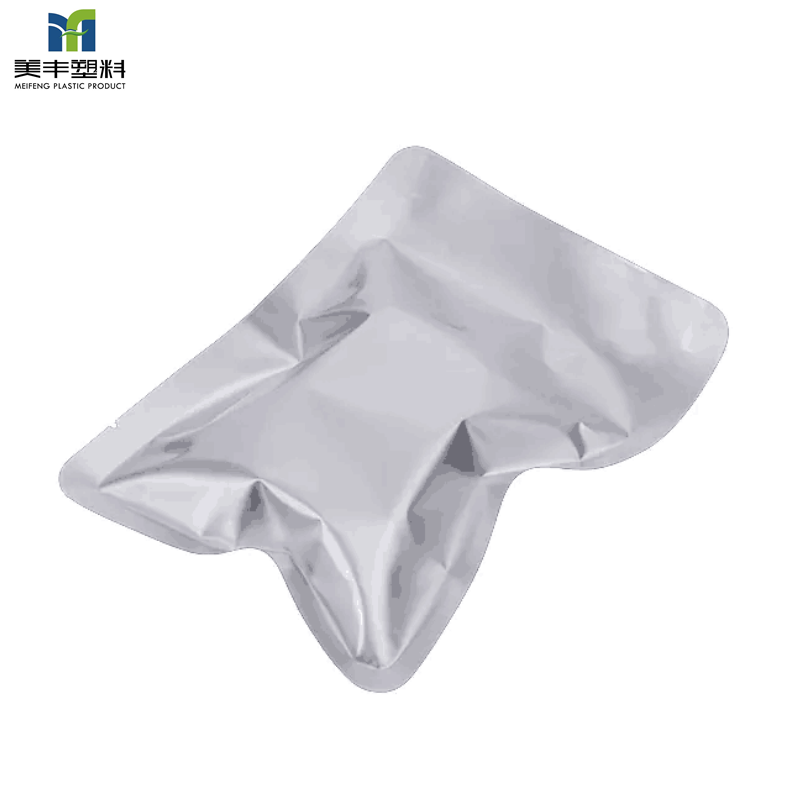

The term “retort” refers to the process of commercially sterilizing food after it has been sealed in an airtight container, such as a flexible pouch or a tray. The food is placed in a large pressure cooker, known as a retort machine, and heated to a high temperature (typically between 240-250°F or 115-121°C) under pressure for a specific duration. This intense heat and pressure combination effectively eliminates all bacteria, spores, and other microorganisms, rendering the food safe and shelf-stable.

This process is a significant evolution from traditional canning, as it often uses modern, lightweight packaging that can be heated and cooled more rapidly, which helps preserve the food’s quality.

The Unmatched Benefits of Retort Food for Your Business

Adopting retort food solutions can provide a competitive edge by addressing some of the most pressing challenges in the food supply chain.

- Extended Shelf Life: With a typical shelf life ranging from 6 months to 2 years, retort products drastically reduce waste and simplify inventory management. The need for a costly cold chain is eliminated, leading to significant savings on transportation and storage.

- Superior Food Quality: The rapid heating and cooling cycles used in flexible retort pouches preserve the food’s original flavor, texture, and color far better than traditional canning. This allows you to offer high-quality, delicious products without compromise.

- Convenience and Portability: Retort food is ready-to-eat and can be quickly reheated in its packaging. Its lightweight and durable nature makes it perfect for applications where portability is key, such as for catering, travel, or military use.

- Guaranteed Food Safety: The sterilization process is a validated and highly controlled method that ensures the complete destruction of harmful pathogens. This provides an unmatched level of food safety and peace of mind for both you and your customers.

- Versatility: Retort technology can be applied to a vast array of products, from soups, stews, and curries to sauces, ready-to-eat meals, and even desserts. This versatility allows businesses to create diverse product lines that meet various market demands.

Key Applications Across Industries

The benefits of retort food have made it an indispensable solution in numerous B2B sectors.

- Food Service & Hospitality: Restaurants, airlines, and catering companies use retort meals and sauces for consistent, high-quality, and easy-to-prepare meal components, reducing kitchen prep time and labor costs.

- Retail & Grocery: Supermarkets and specialty stores offer a wide range of retort products, including single-serve meals, ethnic foods, and camping provisions, appealing to busy consumers looking for convenient, healthy options.

- Emergency & Military Rations: The durability, light weight, and long shelf life of retort pouches make them the perfect choice for MREs (Meals Ready-to-Eat) used by military forces and for humanitarian and disaster relief efforts.

- Co-packing & Private Label: Food manufacturers utilize retort technology to produce shelf-stable, private-label products for other companies, enabling them to expand their brands without significant upfront investment in their own production facilities.

Conclusion

Retort food is far more than a passing trend; it’s a smart, reliable, and cost-effective solution for modern food businesses. By providing superior quality, extended shelf life, and guaranteed safety, this technology offers a powerful way to streamline your supply chain, reduce costs, and deliver exceptional products to your customers. Investing in retort solutions means investing in the future of food.

FAQ

Q1: What is the main difference between retort food and canned food? A: Both use heat to sterilize food, but retort food is typically processed in flexible pouches or trays, while canned food is in rigid metal containers. The more rapid heating and cooling of retort pouches generally result in better preservation of flavor, texture, and nutritional value.

Q2: Does the high heat of the retort process destroy nutrients? A: While all cooking processes can affect nutrients, modern retort technology is designed to minimize nutrient loss. The controlled high-temperature, short-time (HTST) process is more effective at preserving vitamins and minerals than traditional canning.

Q3: Is retort packaging environmentally friendly? A: Retort pouches are lightweight and require less energy to transport than heavy cans. While they are often a multi-layer material that can be difficult to recycle, advancements are being made in recyclable retort packaging to address environmental concerns.

Q4: What types of food are suitable for the retort process? A: The retort process is highly versatile and can be applied to a wide range of food products, including meat, poultry, seafood, vegetables, sauces, soups, and ready-to-eat meals. It is particularly effective for products with a high water content.

Post time: Sep-02-2025