The demand for safe, shelf-stable, and high-quality packaged food continues to rise across global markets. In this environment, the mesin retort pouch plays an essential role, enabling manufacturers to sterilize food efficiently while maintaining product integrity and extending shelf life. For food processors, OEM factories, and packaging suppliers, investing in advanced retort technology is now a key strategy for boosting production capacity and meeting international food-safety standards.

Why the Mesin Retort Pouch Matters in Industrial Food Processing

Retort pouch machines are designed to sterilize packaged food through high-temperature and high-pressure processing. By eliminating harmful microorganisms while keeping flavors, textures, and nutrients intact, the mesin retort pouch has become a preferred solution for ready-to-eat meals, pet food, sauces, beverages, and flexible packaging applications. As export requirements tighten and consumer expectations rise, retort technology provides a powerful competitive advantage.

Key Features of a Modern Mesin Retort Pouch

1. Precise Temperature & Pressure Control

-

Multi-point temperature monitoring

-

Stable pressure balancing system

-

Ensures consistent sterilization for all pouch sizes

2. Flexible Packaging Compatibility

-

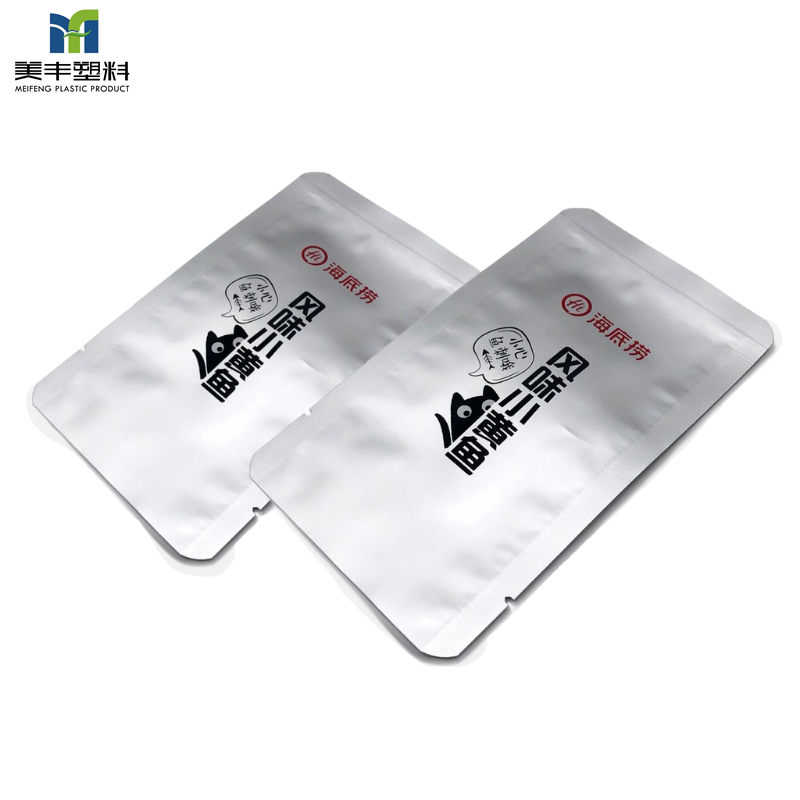

Suitable for aluminum-foil pouches, PET/NY laminates, PP trays, and flexible vacuum bags

-

Supports a wide range of food viscosities and product formats

3. Energy-Efficient Operation

-

Optimized heat-exchange systems

-

Reduced steam consumption

-

Lower long-term operational costs

4. Automation & Safety

-

Fully automatic CIP/SIP cleaning

-

Programmable sterilization cycles

-

Safety interlocks and intelligent alarms

Industry Applications of Mesin Retort Pouch

A mesin retort pouch is widely used across sectors where hygiene, shelf life, and production efficiency are critical:

-

Ready-to-eat meals (RTE)

-

Pet food manufacturing

-

Canned and pouch-based beverages

-

Sauces, curry, broth, soups

-

Seafood and meat processing

-

Baby food & nutritional products

Its versatility makes it a core asset in factories upgrading from traditional canning to flexible modern packaging.

Summary

The mesin retort pouch is a powerful and reliable solution for today’s food-processing industry. Its ability to deliver safe sterilization, support diverse packaging formats, and improve production efficiency makes it essential for manufacturers aiming to expand into global markets. As demand for shelf-stable, ready-to-eat products continues to grow, adopting advanced retort technology will remain a key factor in building competitive, scalable, and compliant food-processing operations.

FAQ:

1. What types of packaging can a mesin retort pouch handle?

It supports foil pouches, laminated pouches, PP trays, and most flexible packaging materials.

2. Is a retort pouch machine suitable for export-grade food production?

Yes. It meets international sterilization and food-safety requirements for global markets.

3. What capacity options are available?

Machines range from small-batch pilot systems to fully automated high-capacity industrial lines.

4. Does the machine require a steam boiler?

Most models operate with steam; however, water spray and hot-water circulation systems are also available

Post time: Nov-18-2025