In recent years, retort pouch packaging has emerged as a dominating packaging solution across both the human food and pet food industries. The retort stand-up pouch, retort bag, retort packaging, and other flexible pouch formats are replacing traditional cans and jars due to their convenience, durability, and performance under high temperature sterilization. According to market research, the global retort packaging market was valued at USD 5.59 billion in 2024 and is projected to reach over USD 10 billion by 2033.

Rising Demand Across Food & Pet Food Applications

Whether for wet pet food retort bags, dog food retort packaging, cat food retort pouch, ready-to-eat meals, or shelf-stable sauces, manufacturers and brands are turning to high barrier retort pouches to meet consumer expectations of freshness, safety and convenience. These bags are engineered to withstand sterilization temperatures of 121–135°C and provide extended shelf life while maintaining product integrity.

Material Innovation & Differentiation

Retort pouch materials vary greatly depending on product needs. Some key structural options include:

1. A three-layer transparent film construction offering good performance with visibility of contents.

2. A four-layer aluminum foil structure delivering superior barrier protection against oxygen, moisture and light.

3. Transparent high barrier pouches or aluminum retort pouches tailored for pet food applications or high end ready meals.

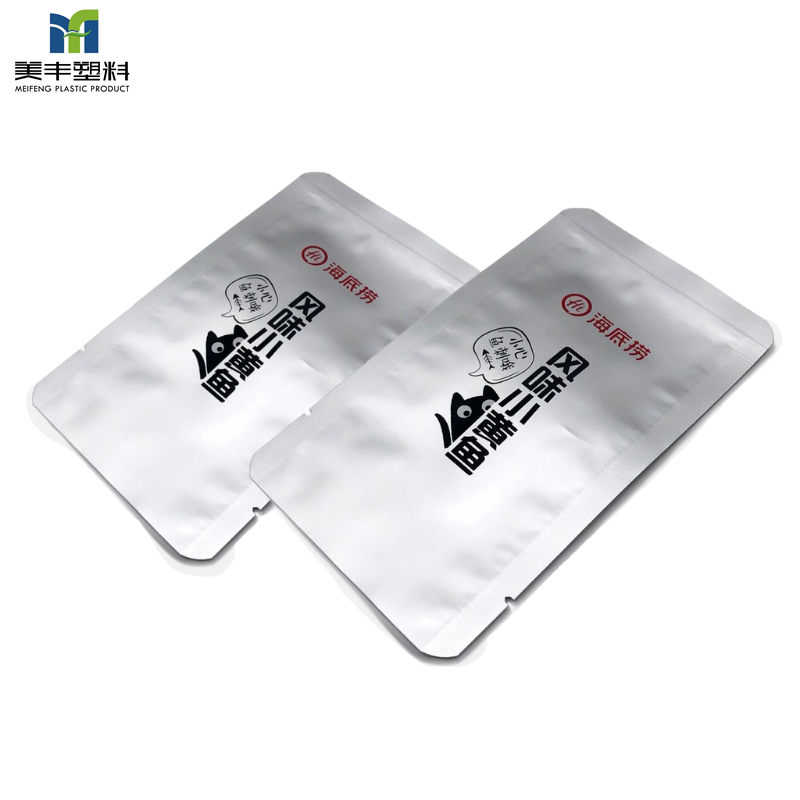

The choice of retort pouch material, whether “transparent retort pouch” or “aluminum retort pouch”, plays a critical role in determining the bag’s suitability for high-temperature sterilization and long shelf life. Innovations in film technology and printing methods (such as gravure printing and digital printing) further enhance the appeal of custom retort pouch packaging.

Why Custom Retort Pouches Matter for Brands

For brands looking to enhance shelf appeal and differentiation, custom high-temperature retort pouches with printed designs and structural features such as zipper closures or spouts offer both premium presentation and functional benefits. The flexible format reduces weight compared to rigid containers, lowers shipping cost, and improves convenience for end-users. According to industry reports, stand-up pouch formats including retort versions are gaining traction for their display performance and convenience.

What This Means for Packaging Suppliers

As a packaging factory specialising in high temperature sterilisation pouches, retort stand-up bags, and custom printed retort pouches for food & pet food, you are in a favourable position. You can address key demands of global customers:

1. Bags capable of withstanding 120-135°C sterilisation.

2. Use of four-layer/three-layer constructions: aluminum foil or transparent high barrier.

3. Custom printing, flexible order quantities, and support for both food and pet food applications.

Call To Action

If you’re seeking a reliable manufacturing partner for retort pouches – whether for pet food wet bags, dog food retort packaging, or ready meals – we invite you to contact us. Leave a message on our website or request a sample today. Discover how our high-barrier retort packaging solutions can elevate your brand and protect your product.

Post time: Nov-05-2025