In today’s fast-paced manufacturing and food processing industries, aluminium retort pouches have become a crucial innovation for safe, efficient, and long-lasting packaging. These pouches combine durability, heat resistance, and barrier protection, making them a preferred choice in both food and non-food applications. For B2B buyers, understanding the benefits and applications of aluminium retort pouches is essential to improving product shelf life and maintaining quality standards.

What Is an Aluminium Retort Pouch?

An aluminium retort pouch is a multilayer laminated packaging material designed to withstand high-temperature sterilization, typically up to 121°C (250°F). It is made of several layers, including polyester (PET), aluminium foil, and polypropylene (PP), each serving a distinct function:

-

PET (polyester): Provides mechanical strength and printability.

-

Aluminium foil: Offers an excellent barrier against oxygen, light, and moisture.

-

PP (polypropylene): Ensures heat-sealability and product safety during sterilization.

This structure allows products to be safely stored and transported without refrigeration while preserving flavor, texture, and nutritional value.

Key Advantages of Aluminium Retort Pouches

-

Extended Shelf Life

-

Protects against air, moisture, and light.

-

Maintains freshness for 12 to 24 months without preservatives.

-

-

Lightweight and Space-Efficient

-

Reduces shipping and storage costs compared to traditional cans or jars.

-

Flexible design minimizes packaging waste.

-

-

High-Temperature Resistance

-

Suitable for sterilization and pasteurization processes.

-

Maintains structural integrity during thermal treatment.

-

-

Eco-Friendly and Safe

-

Uses less material than rigid packaging, reducing environmental impact.

-

Can be designed with recyclable or biodegradable layers.

-

-

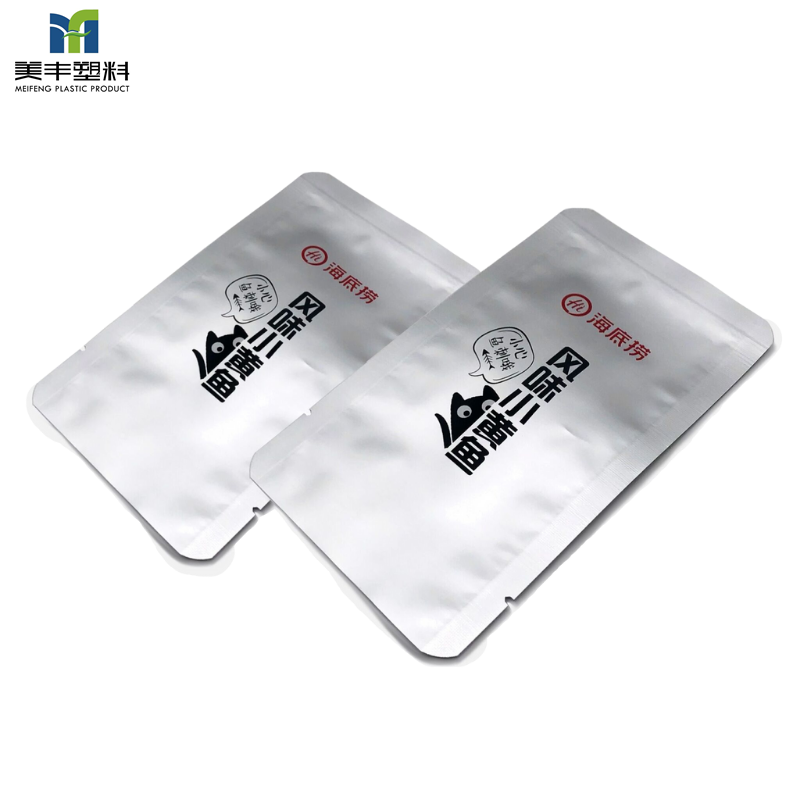

Customizable for Industrial Needs

-

Available in various sizes, sealing styles, and printing options.

-

Can be tailored for both food and chemical packaging.

-

Common Applications

Aluminium retort pouches are versatile and widely used across industries:

-

Food Industry: Ready-to-eat meals, soups, sauces, pet food, coffee, and dairy products.

-

Pharmaceuticals: Medical liquids, sterile supplies, and diagnostic kits.

-

Chemicals and Lubricants: Industrial pastes, gels, and cleaning agents.

-

Defense and Outdoor Use: Military rations (MREs) and camping meals.

Quality and Compliance Standards

High-quality aluminium retort pouches comply with international packaging standards such as:

-

FDA and EU food contact safety regulations.

-

ISO 9001 quality management certification.

-

HACCP and BRC guidelines for hygienic production.

Manufacturers employ advanced lamination and sealing technologies to ensure durability and prevent leakage or contamination during distribution.

Conclusion

The aluminium retort pouch represents the future of efficient, sustainable, and high-performance packaging. For manufacturers, distributors, and food processors, it offers a balance of durability, safety, and cost-effectiveness. As global demand for ready-to-eat and long-shelf-life products continues to grow, aluminium retort pouches will remain a key player in modern packaging innovation.

Frequently Asked Questions (FAQ)

1. What is the main advantage of aluminium retort pouches over tin cans?

They are lighter, take up less space, and reduce transportation costs while offering equal or better protection.

2. Can aluminium retort pouches be microwaved?

No. Because they contain an aluminium layer, they are not suitable for microwave use.

3. Are aluminium retort pouches safe for long-term food storage?

Yes. They are sterilized and hermetically sealed, ensuring safety for up to two years without refrigeration.

4. Can these pouches be recycled?

Some designs use recyclable materials or mono-layer structures to support sustainability initiatives, depending on local recycling systems.

Post time: Oct-28-2025